How can a new SAP ERP standardize processes and reporting?

A large manufacturing company with operations in more than 10 countries realized that their legacy ERP system, implemented 15 years ago, had become outdated and was causing multiple issues. Each of the locations was operating a customized version of the platform and that led to data inconsistencies and high maintenance costs. In addition, various geographies and functions were using several non-standard applications for various processes, everything adding up to massive reporting inconsistencies. Due to version differences and a high degree of local customization, creating standardized reports led to high costs.

The company needed a modernized ERP platform which could serve as a common source of information and data across various functions and locations. They required an ERP system which would not only standardize data processes but would also be able to create a unified information management umbrella across various functions, including finance, sales, procurement, inventory management, production, quality and plant maintenance.

The company sought a solution provider with deep expertise and experience with SAP platforms, which was their preferred ERP solution. They were looking for an SAP partner with global reputation, as well as the expertise and capability to understand their organization and industry. After evaluating several top SAP solution partners, the company chose to work with EY owing its reputation as a key alliance partner for SAP and its in-depth knowledge about the manufacturing industry.

We implemented the SAP ERP leveraging our deep industry knowledge.

EY worked with the manufacturing company to replace its existing legacy ERP platform with a modern SAP ERP platform. The solution incorporated deep knowledge and expertise about the manufacturing industry and helped redefine some of its existing processes to make them more efficient. For example, the ERP helped the company redefine its material management processes for improved efficiency.

The company initiated the ERP implementation to aid its future growth and expansion plans. The ERP had to be capable of seamless information flow across different functions and geographies.

To enable the implementation, the team comprised personnel from the company’s various businesses and IT. EY had its key resources on-site to ensure effective collaboration amongst the different constituencies and stakeholders involved with the implementation. The EY team approached the implementation with a strong consulting mindset to ensure that potential gaps in the future are addressed along with tactical issues. EY chose its team based on various capabilities such as knowledge about the industry coupled with knowledge about SAP platforms.

Figure 1: Capabilities to implement SAP ERP at a manufacturing company

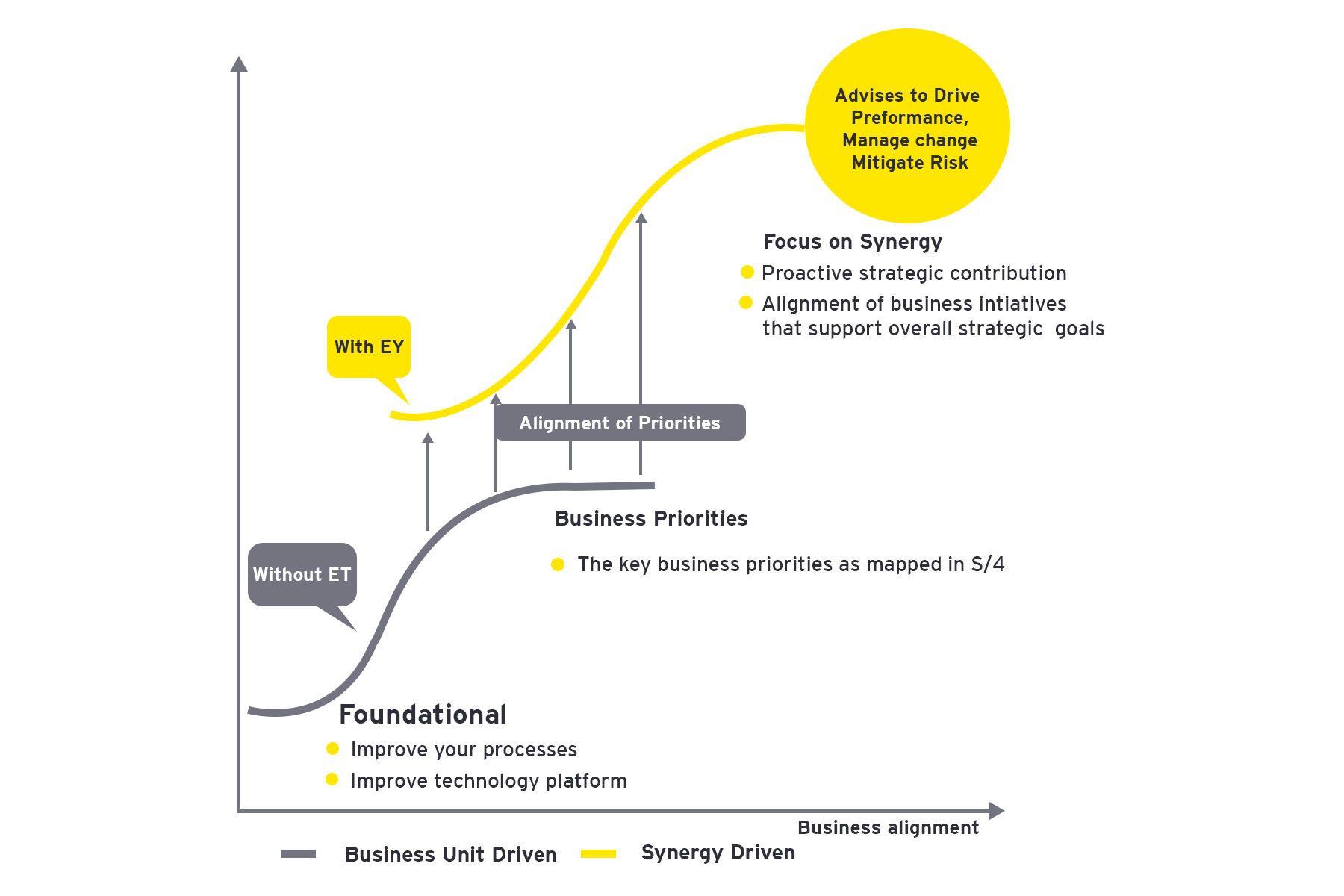

EY’s approach was based on the company’s vision and strategic requirements. The team supported the company with change management, program management, governance and consulting skills to ensure success of the project. We also helped build an improved analytics and reporting dashboard for the management of the company.

The new ERP improves processes and enables better decisions

With the ability to standardize reporting and processes across locations and functions, the company saw positive changes in its ability to align with strategic priorities. The team completed the implementation within a period of 12 months.

Figure 2: Alignment of strategic priorities after SAP implementation

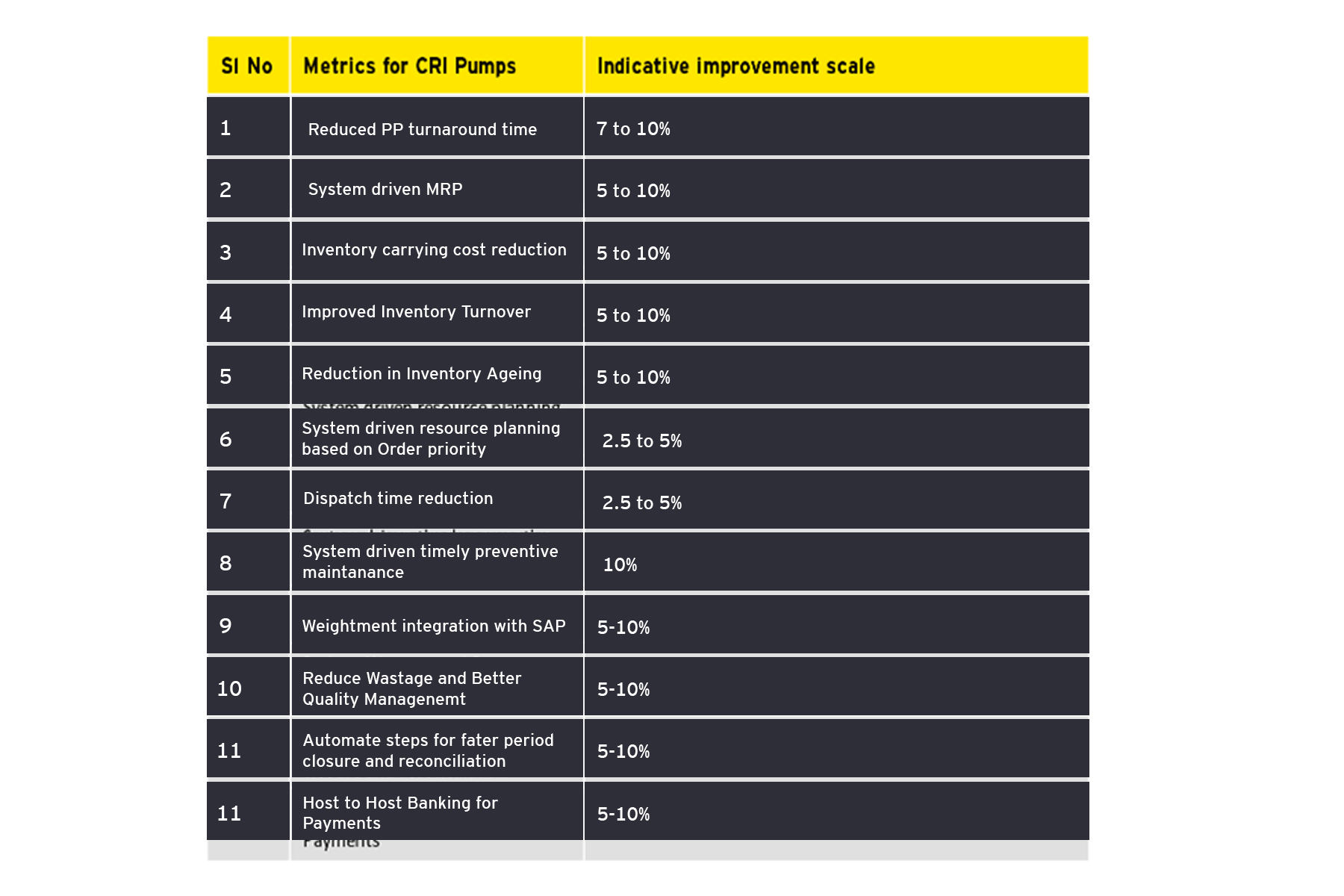

The company witnessed improvements in efficiencies across various processes and reporting across various functions.

Figure 3: Improvements in outcomes after implementation of new SAP platform

The manufacturing company was able to accomplish three distinctive outcomes from the new ERP implementation. First, it was able to digitize various processes which the previous ERP system was incapable of. Second, the ERP helped the company standardize processes across various functions. Third, the implementation standardized reporting across various business constituencies, enabling the management to make better strategic decisions.

Related content

The team

Contact us

Interested in the changes we have made here,

contact us to find out more.